|

|

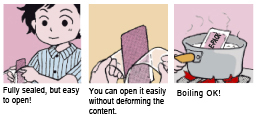

Everybody - from children to the elderly - can open it easily with limited strength. Tensile Strength: 300-700g/15mm width. |

|

Each sealed edge is heat-sealed so that the filling is completely cut off from the outside world. EPACK film can be laminated with materials with barrier properties including aluminum, or the decoration materials such as Japanese paper to protect the filling. |

| The perfect fluid sealing upon filling and packaging of liquid or paste products can prevent air from entering the package. (Oxidation-/mold-/deterioration-resistant) |

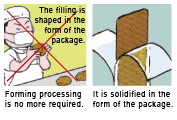

| EPACK solidifies the filling in the package, so the product can be formed with its thickness adjusted during the filling/packaging process. When used with the cooling system, it can both enhance the efficiency and enable the laborsaving in the production line at the same time. |

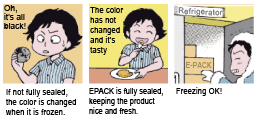

The fluid sealing does not allow air to remain in the bag, so the product does not get oxidized, discolored, or dried and dehydrated if it is not frozen for a long time. The fluid sealing does not allow air to remain in the bag, so the product does not get oxidized, discolored, or dried and dehydrated if it is not frozen for a long time. |

The sealed edge is not affected even if the package is boiled or frozen after the filling, and remains easy to open. The sealed edge is not affected even if the package is boiled or frozen after the filling, and remains easy to open. |

A product that requires the forming process, such as hamburger, can be formed in the shape of the bag, so the process can be omitted, resulting in saving in labor. A product that requires the forming process, such as hamburger, can be formed in the shape of the bag, so the process can be omitted, resulting in saving in labor. |

Universal Design Just a sheet of film is left after E-PACK is opened. It helps to reduce waste in comparison with other product with the same purpose.

|

|

● Target Products Anything to be "solidified" that is filled in fluid condition and coagulable when frozen or boiled, such as: yokan (thick jellied Japanese traditional sweet), chocolate, jelly, cheese, sticky rice cake, soap, bath agent, air freshener, wax, lard, savory pancake, hamburger, fish sausage, minced fish ball, egg, arum root, tofu, ice, ice cream, bread dough, food boiled in soy sauce The range of target products can be expanded infinitely with your idea for any industries including food, pharmaceutical, cosmetics, and chemical production. ● Features The perfect fluid sealing upon filling and packaging can prevent air from entering the package. (Oxidation-, mold-, and deterioration-resistant) The product can be formed with its thickness adjusted during the filling/packaging process, so the efficiency of the production line is greatly improved. The possibility to acquire the new market will be expanded just by switching the package of the existing products to the "EPACK". |

|

EPACK is developed by the packaging machine manufacturer through the project to seek for a unique product that is differentiated from the various forms of existing products on the market.

We believe that we are capable of assisting you in the various stages, from the production plant to the final packaging line. We have applied for 17 industrial properties in the development phase (both in Japan and overseas, some already acquired). Due to the characteristics of the packaging features, special packaging film is employed so the compatibility with the filling content is very important. To enable the secure product production (which we give the highest priority), we provide you with the total support for the supply of packaging material you use and the maintenance of the machines. From the experimental production to the seminar for machine installation, we are ready to provide support such that even new businesses can start the production. * Please note that the treatment differs from our existing machines. |

|

Leading food manufacturers both in Japan and overseas have already launched their new products in "EPACK". We are presently carrying out the development and trial manufacture of new products with several leading food manufacturers. |