|

| Select the inspection equipments according to the purpose, from the one to be used to define the packaging specifications (such as volume, seal strength, and withstanding pressure) to the one to be used in the packaging line (such as detecting metal, weighing, and sorting). |

| |

|

|

|

|

|

|

|

Pressure Tester

(for Liquid)

|

|

Tensile Tester |

|

Leak Tester

(for Powder)

|

|

Pressure Test Paper |

Put a certain level of pressure upon the packaged product to check whether the compression strength meets the packaging specifications.

Ex.: Acceptable if there is no peeling of sealed part or tear of the pack under the pressure of 100kg for one minute.

|

|

Cut the sealed surface in a 15mm width and pull both ends slowly to

check whether the seal strength meets the packaging specifications.

Ex.: Not acceptable if the sealed surface comes or the laminated part is separated under 3kgf.

|

|

Check whether the air leaks from products with the barometric pressure decreased to a certain level.

Ex.: Acceptable if there is no air leakage with 50cmHg.

|

|

Check whether the sealing parts of the packaging machine are meshed with each other evenly at a certain pressure.

|

|

| |

|

Here are the optional equipments that can be attached to the packaging machine. Select the equipments according to the purpose, from the bag-making-related options to the optional pump/measurement apparatus for filling.

* The equipment may differ from the pictures shown depending on the model.

|

| |

|

|

|

|

|

|

|

| Micro Gate |

|

Auger Measuring Apparatus |

|

Parts Feeder |

|

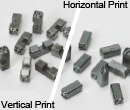

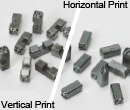

Coding Digit (vertical/horizontal) |

|

| |

|

|

|

|

|

|

|

| Hopper Level Detector |

|

Slide Cutter |

|

Slitter |

|

Cartridge Rolls |

|

| |

|

|

|

|

|

|

|

|

Adjustable Film Lead

(Type E)

|

|

Adjustable Film Lead

(Type R)

|

|

Stirrer

(M・2M)

|

|

|

|

| |

|

|

|

|

|

|

|

Sorting Equipment

(3 Directions)

|

|

Sorting Equipment

(Left/Right)

|

|

Sorting Equipment

(Shutter)

|

|

|

|

| |