Automatic Filling/Packaging Machines

Other Technologies

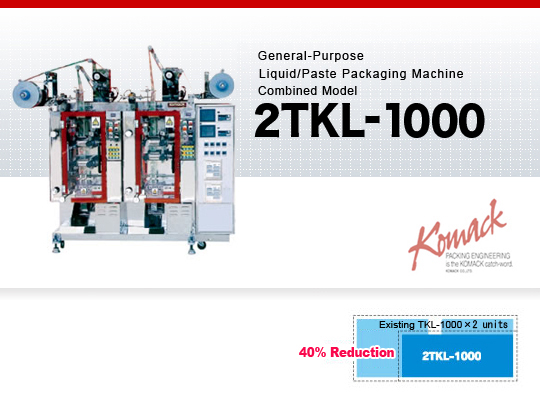

2TKL-1000

Dual Row General-Purpose Liquid & Paste Packaging Machine

2TKL-1000 is the dual version of TKL-1000, the versatile and cost-reduced machine, which is equipped with the minimum necessary features. This two-in-one machine can save space and contribute to high performance. It is equipped with the mechanisms to operate in accordance with the packaging conditions required by each product specifications. Among such standard mechanisms are; photoelectric controlled the pattern matching or endless operation, change in pitch, adjustment of the notch depth and fine-tuning of cut position and angle. Also, the pump can be selected from a wide range of pumps for consecutive and intermittent discharge. Other optional features are omitted as much as possible to achieve the low cost.

Standard Specifications (Single)

| Filling | Liquid & paste | |

| Package Form | 3-side sealing, 4-side sealing (Single/Double) | |

| Packaging Capacity | 20-300 bags/min.~2 | |

| Filling Volume | 3-100 cc | |

| * The range of the filling volume may vary by the gproperty of the filling materialh and the gfeeding deviceh. | ||

| Bag Size | 25-100 mm | |

| Length | Divided in 3: 80-200mm, Divided in 4: 60-150mm Divided in 6: 40-100mm |

|

| Number of Rows of Roll | 3 | |

| Film | Width | 50-200 mm |

| Diameter | 400 mm (Max.) | |

| Feeding Speed | 15 m /min. (Max.) | |

| * Actual filling speed may vary by the product pitch, the film material and the property of the filling material. | Power Consumption | Main Motors | Single phase 200 V, 1.5 KW (Total) |

| Heater | 1KW ~4, Side: 0.3KW~ 4 | |

| Total Power | 5.5 KW | * Power consumption may vary by the selected optional equipments including the filling pump. |

| Total Power | 12.0 KW | |

| Dimensions of Machine | W 1,920~ L 860~ H 2,100(mm) | |

| Weight of Machine | Approx. 1500 kg | |

(Note)

1. The packaging capacity, filling volume and the package size may vary by the selected options. Please contact us for details.

2. The range of the length of the bag may vary by the width of the side seal.

3. The actual filling speed may vary by the film material and the property of the filling material.

4. The range of the filling volume is determined by the gviscosity of the filling materialh and the gfeeding pumph. Please feel free to consult with us.

5. The total power may vary by the specifications of the pump and other optional equipments.